Assembly Projects

Project Performer

( Physical Project )

Top Skills Utilized:

CAD - SolidWorks Parametric Modelling & SolidWorks Simulation

Metal Fabrication and MIG Welding, etc.

Fiberglass Molding and Vinyl Wrap coating.

Electrical wiring ( BLDC Motor - Battery - Controller - Other equipment)

On-Road Testing.

-

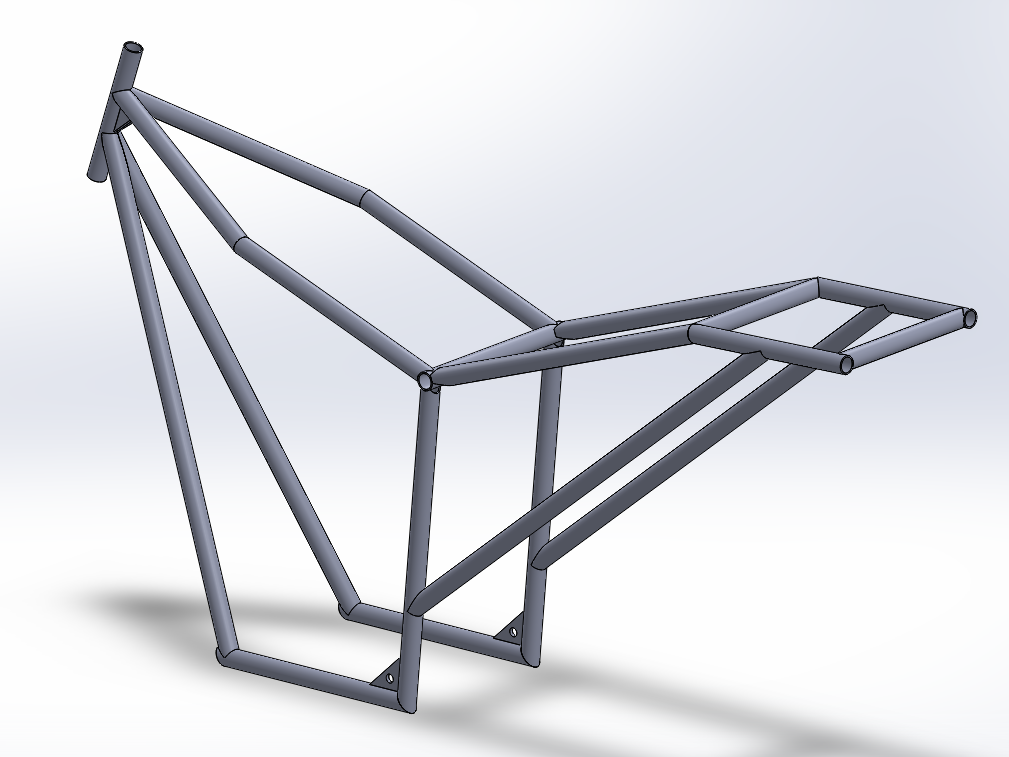

SolidWorks Model

Used a Concept to design the main frame of the E-Bike. It helped me plan how to organized all the equipment and ergonomics of the Bike.

-

Frame

Used 1.5 & 2.5 inches metal tubes and MIG Welding method to fabricate strong metal frame.

-

Chassis

After Painting Frame, all the essential mechanical and electrical components were added to construct functional chassis of the E-Bike.

-

Clay Modelling

Used clay-modelling process to shape the body of the bike.

-

Fiberglass Body (FRP)

Later, Fiberglass body was constructed, copying the shape of the clay model.

-

Electrical Wiring

Body was coated with Vinyl wraps and other electrical components were added such as Light, horn, Indicators etc.

-

Final Look

Final Look of the E-bike before electrical Enclosure.

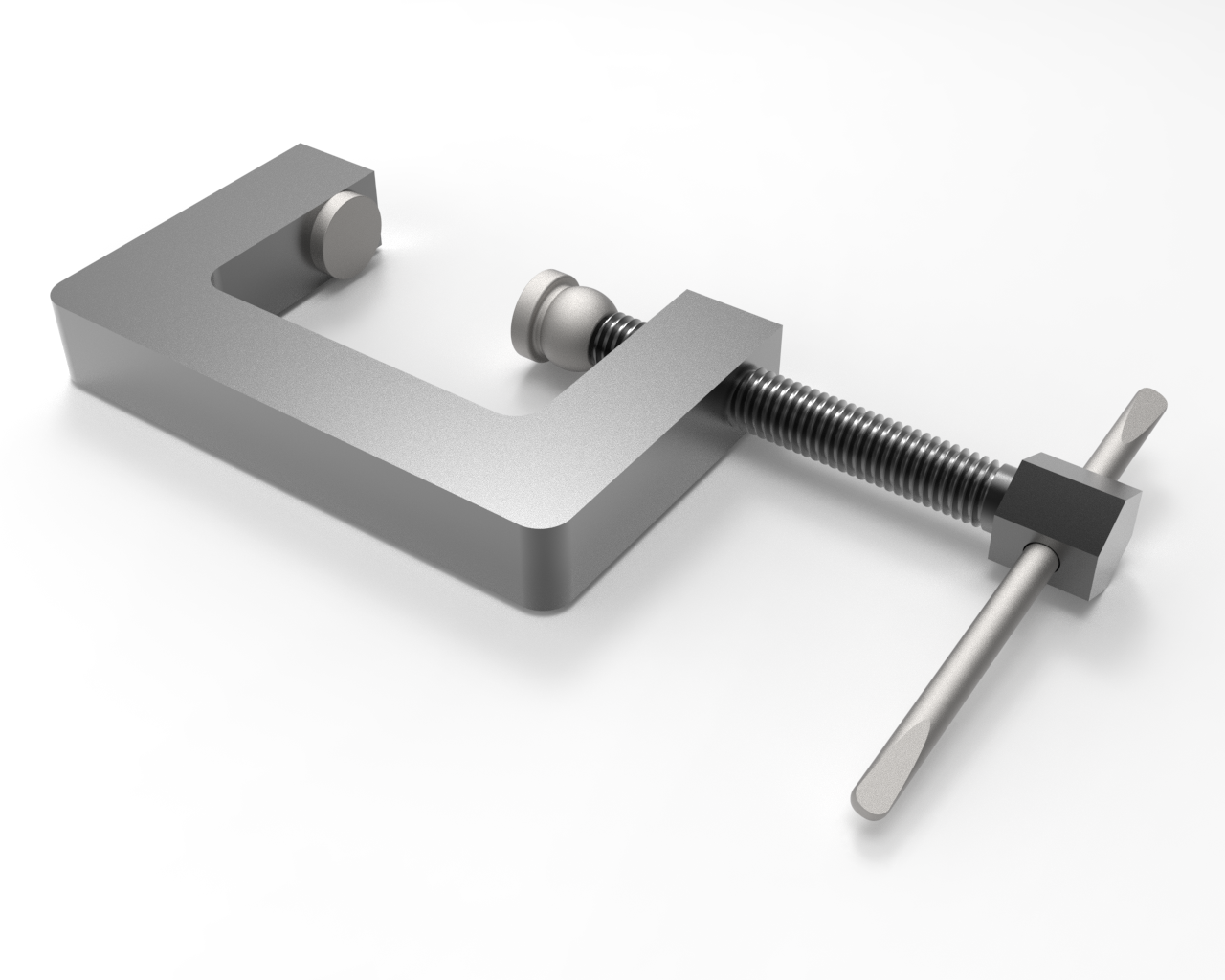

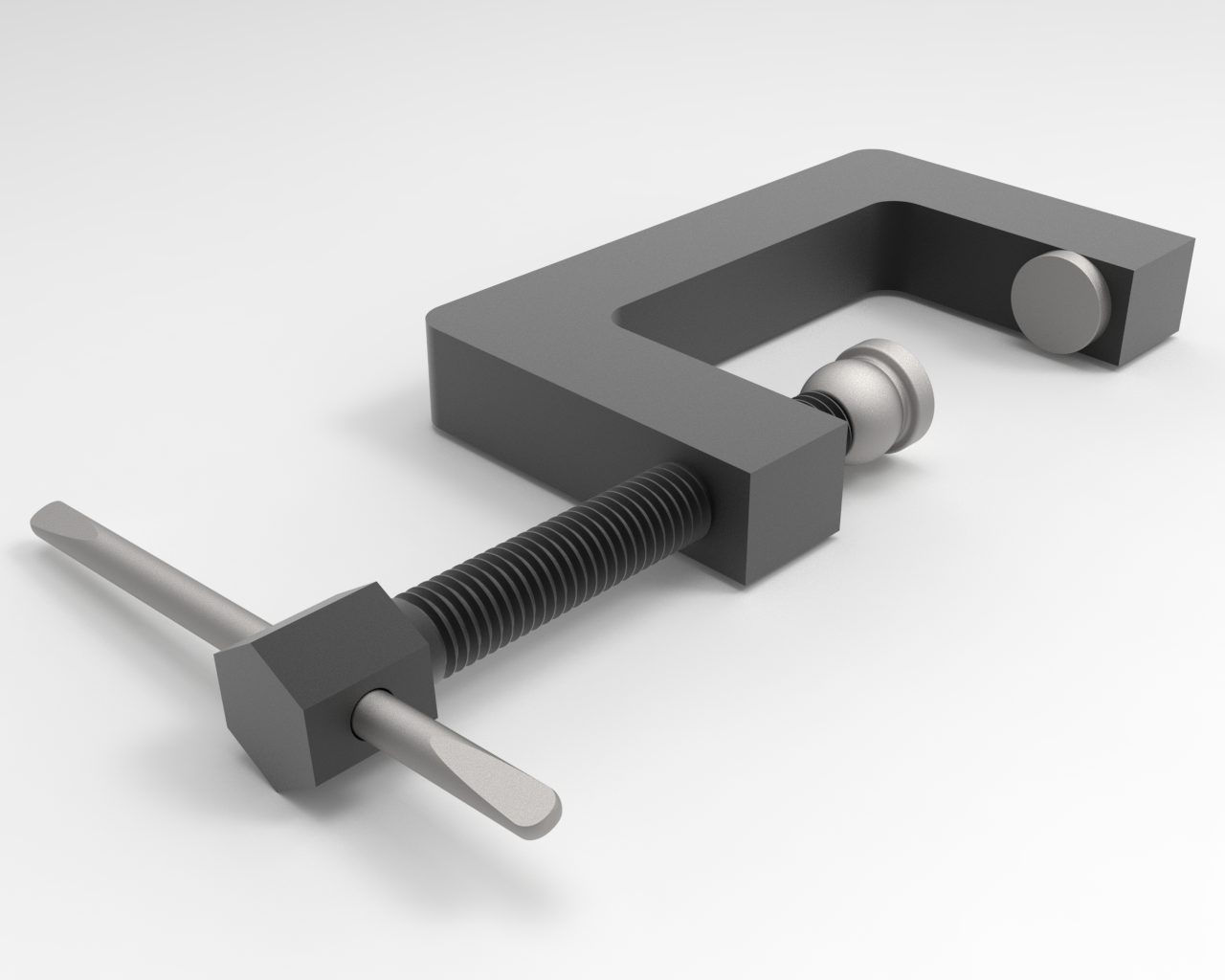

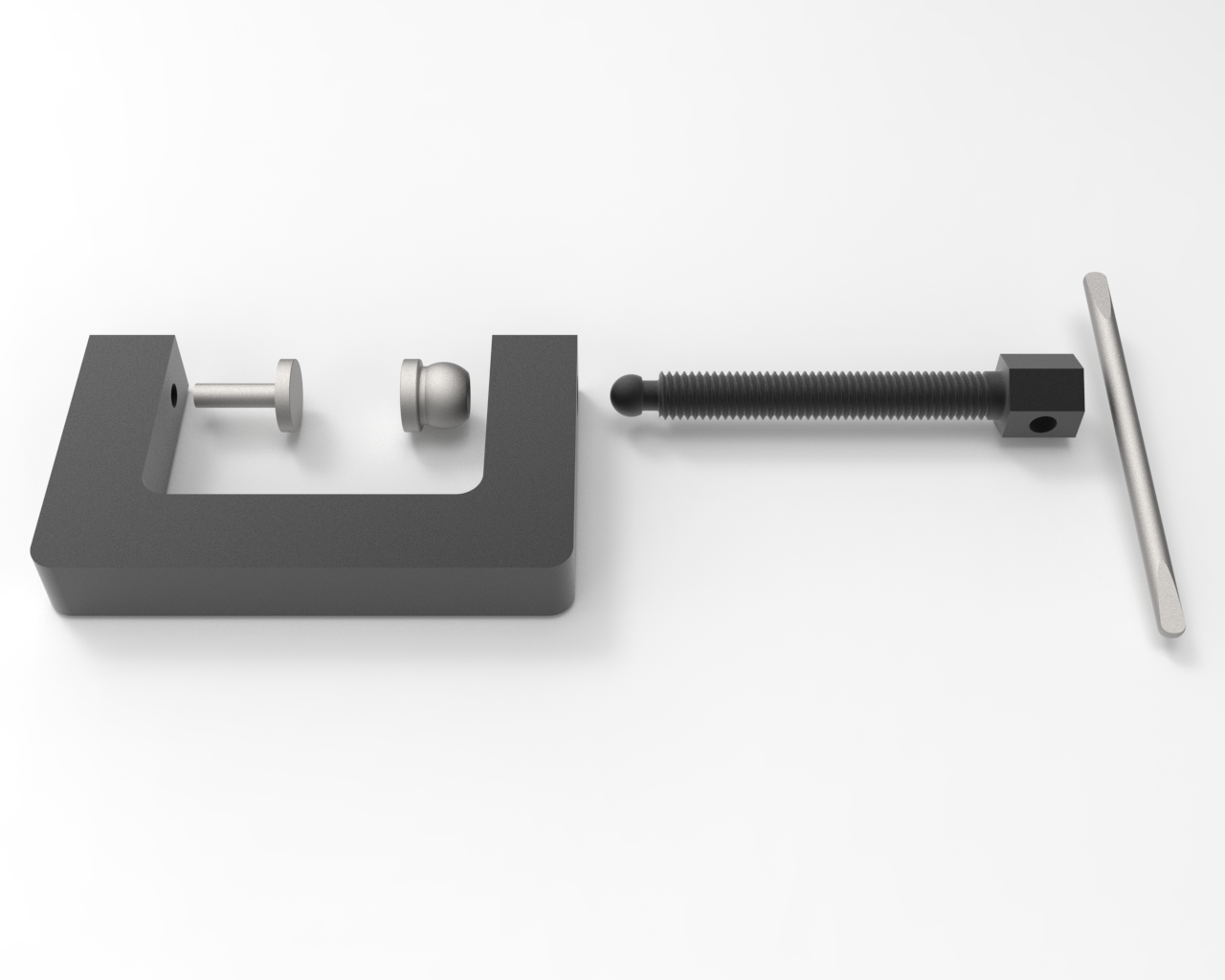

C-Clamp

( Physical Project )

Top Skills Utilized:

SolidWorks CAD: 3D Modelling, component assembly, exploded view, GD&T, standard fasteners.

Design for Cost, and manufacturing.

Keyshot Rendering

-

SolidWorks Model

Using 2D drawing, created 3D assembly.

-

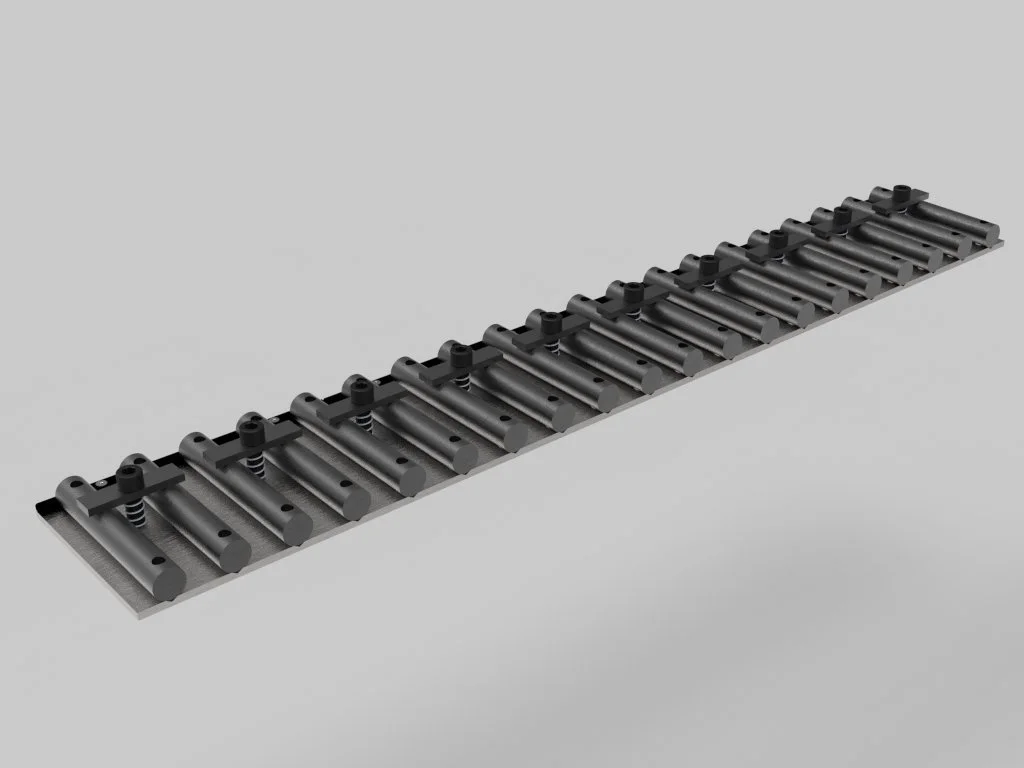

Exploded View

5 unique parts assembly.

-

Physical Part

Machined components using manual lathe and milling machine.

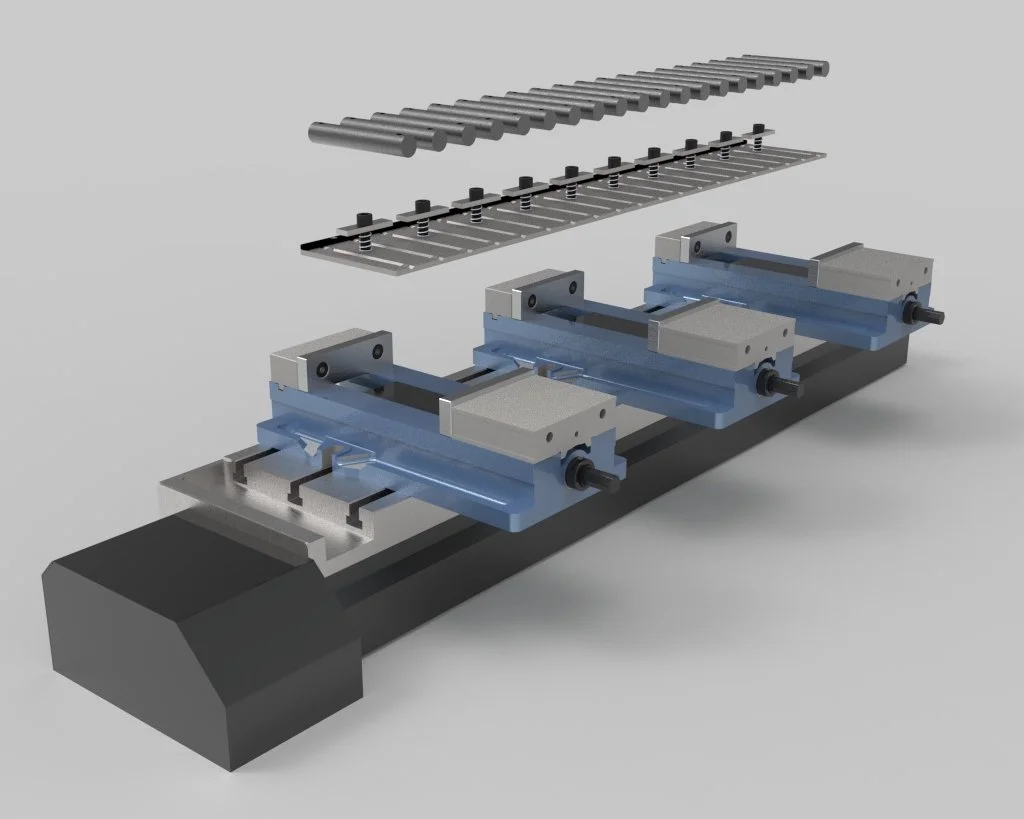

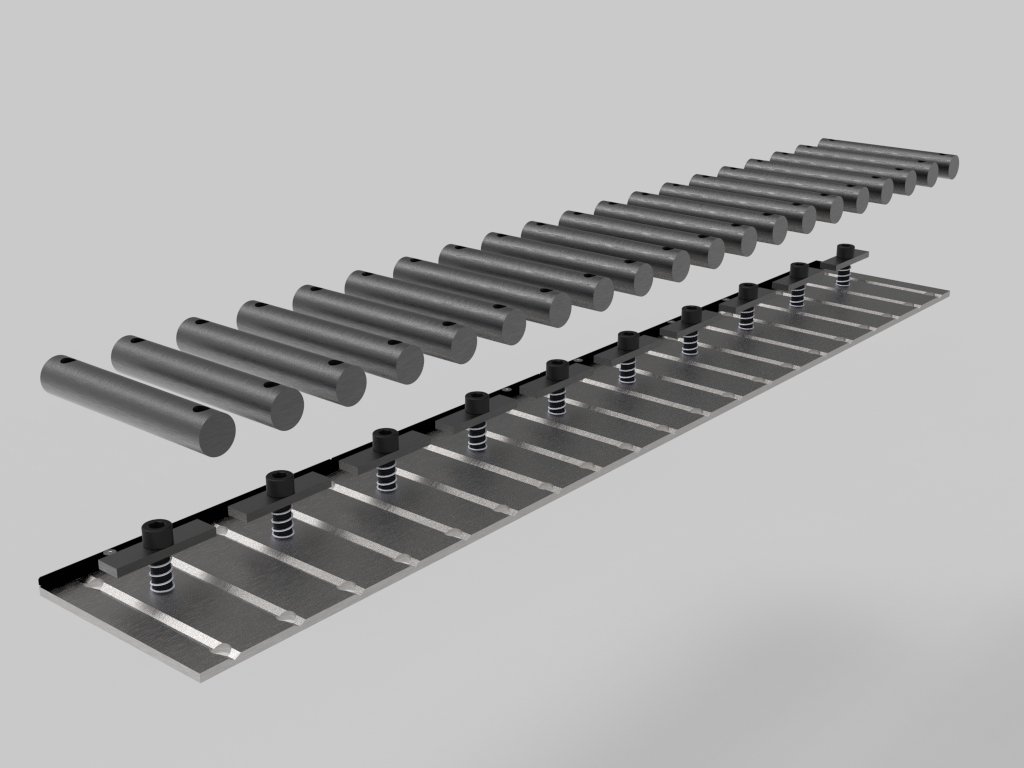

CNC Fixture

( Designed Project )

Top Skills Utilized:

SolidWorks CAD: 3D Modelling, component assembly, exploded view, GD&T, standard fasteners.

Design for Cost, and manufacturing.

Keyshot Rendering

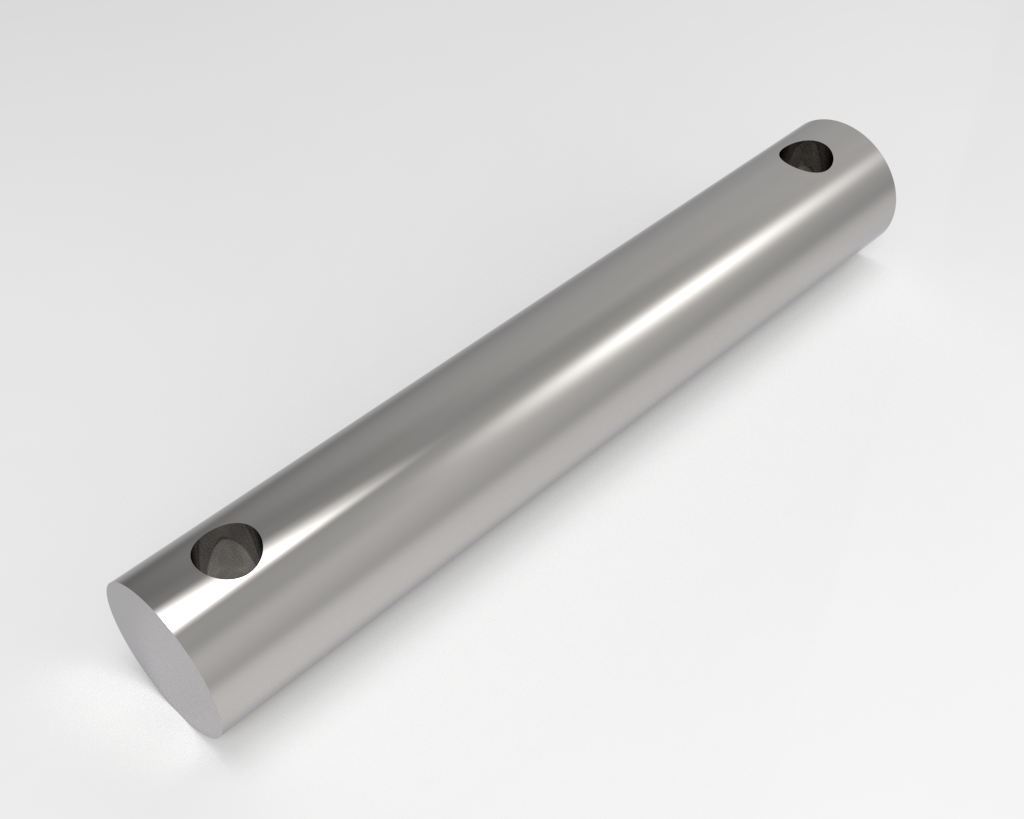

Purpose

Production part: High-volume production of a pin, 1” in OD and 6” in length,

Machining: Two identical holes are required to be machined on each part.

This fixture securely holds 20 pins in a single setup.

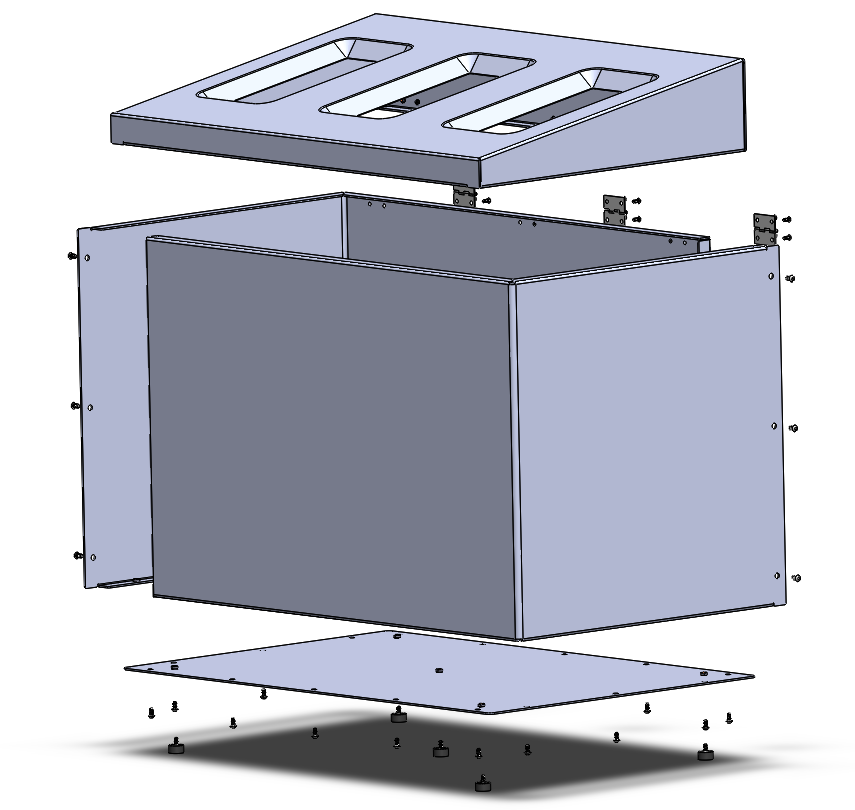

Dustbin

( Designed Project )

Top Skills Utilized:

SolidWorks CAD: SolidWorks Sheet Metal, and PEM Fasteners.

Design for Cost, assembly and manufacturing.